According to recent statistics, the snack food market is expected to grow at an unprecedented rate, and the market demand will also continue to grow, stimulating more investors to enter the industry. Among various food products, snacks are the most commonly consumed packaged food. It has led to improvements in machining to meet the needs of the market. Machine suppliers are now turning to building automated machines to match their competitors.

The packaging machine is at the center of it all. These devices are required for quality packaging and customization of snack packs. This article will guide you on how to use a packaging machine to package snacks for sale while promoting your business.

The packaging of snacks is done with various packaging materials. The most common are bags and cans. These two packaging materials are popular for their properties and the benefits they provide for snack foods.

Here we mainly talk about the bag packing machine.

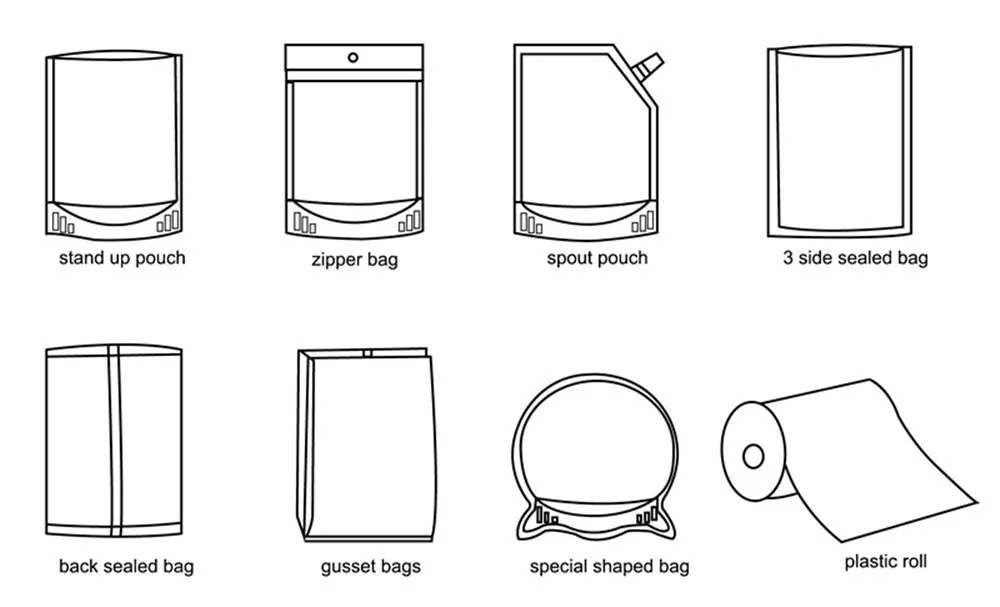

Different bag types:

Plastic or paper bags are considered flexible packaging options. This is a beneficial property for packaging materials, as it keeps its contents safe. There are different pouches; stand up pouches, gusset pouches, nozzle pouches, nozzle pouches etc.

The features of snack bags:

1. Easy to seal the bags.

2. Easy to open and release.

3. Eco-friendly material.

4. Bags come in a variety of designs.

5. Their light weight means easier and cheaper shipping.

6. Pouches extend the life of snacks by helping them stay fresh for longer.

7. Provide cost savings for snack suppliers.

Types of snack packaging machines:

In order to cater to the development of the snack industry, packaging machine manufacturers have launched many snack packaging machines for different needs. We manufacture various of machines models for snack packaging including: popcorn packaging machine, nuts packaging machine, gummy packaging machine, jerky packaging machine, etc.

What can you benefit from a snack packer?

1. Increased production: Automatic packaging lines are more efficient, faster and more precise when packaging snack foods. With these features, you'll pack more products to meet market demand and avoid running out of products in retail stores.

2. Quality assurance: Packaging lines help meet industry standards by ensuring packaging is done carefully and correctly. Containers passing through the packaging line are well sealed, promoting snack preservation.

3. Reduce waste: It's no secret that packaging materials and food are wasted in the packaging process. Unlike manual machines, automatic packaging lines reduce waste at an astonishing rate. Since the machine has a PLC system, you just program it with the measurements you want and make it work.

4. Minimal on-the-job injuries: There is always a risk of injury in any industrial process involving workers; however, incorporating a packaging line into your business will ensure that the risk is reduced or eliminated.

5. Sophisticated designs are achievable: the packaging line allows you to customize packaging containers while incorporating the latest branding concepts.

Making a profit and growing your brand is always a top priority for every business owner. In the packaging industry, achieving these aspects does not have to be so stressful. Investing in a quality packaging line for your business will give you the results you want and more benefits.

How does the machine work?

You must first program the PLC system with the package details before the process begins.

1. First of all, the Z-type elevator will automatically transport the product to the full scale of the group. The combined scale will weigh according to the weight set on the touch screen.

2. After the weighing is completed, it will automatically drop to the packaging machine for bagging, sealing and cutting.

3. Finally, the finished bag will be conveyed from the finished product conveyor.

If you are interested, more details can be found in this previous article: How do pouch packaging machine work?

Copyright © CoreTamp All Rights Reserved | Sitemap | Powered by