Application

Coretamp provides a 4-12 stick bag granule sachet filling machine that can produce 180-480 bags per minute, Suitable for packaging various uniformly dense granular materials (sugar, pharmaceutical particles, coffee particles, particle desiccants), this equipment has the characteristics of fast packaging speed, high accuracy, low energy consumption, and labor saving.

We also provide secondary counting and packaging solutions, such as placing small bags into large outer bags and sticking bags into paper boxes.

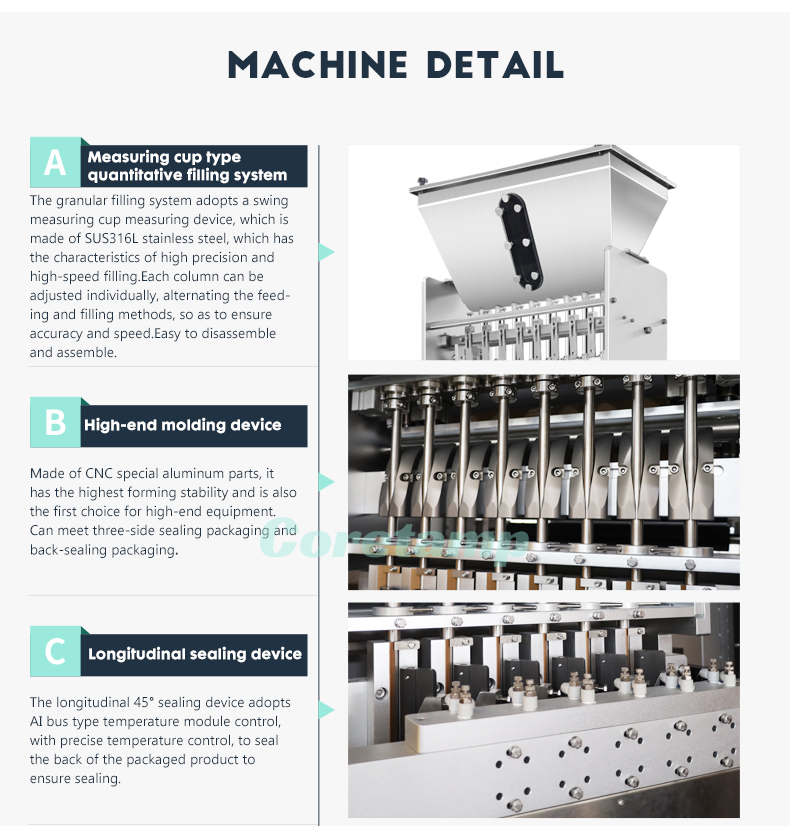

The multi lane packaging machine can simultaneously produce multi lane sachets. The multi-channel packaging machine can produce multi-channel bags simultaneously. The particle filling system adopts a swinging measuring cup measuring device, which has the advantages of no blockage, higher accuracy (accuracy+-0.1 g when filling 1-5 grams), and fast filling. The dosage of each column can be adjusted separately, and the material filling method is alternated to ensure accuracy and speed. Easy to disassemble and clean.

The characteristics of the granular small bag filling machine:

1. The surface of the packaging machine adopts anti fingerprint technology, which is easy to clean

2. The particle small bag packaging machine is made of specially thickened SUS304 stainless steel, and the part in contact with the material is made of SUS316L stainless steel, which has advantages such as corrosion resistance, rust prevention, and no change in material properties

3. In response to the trend of Industry 4.0, it can be connected to SCADA and MES systems

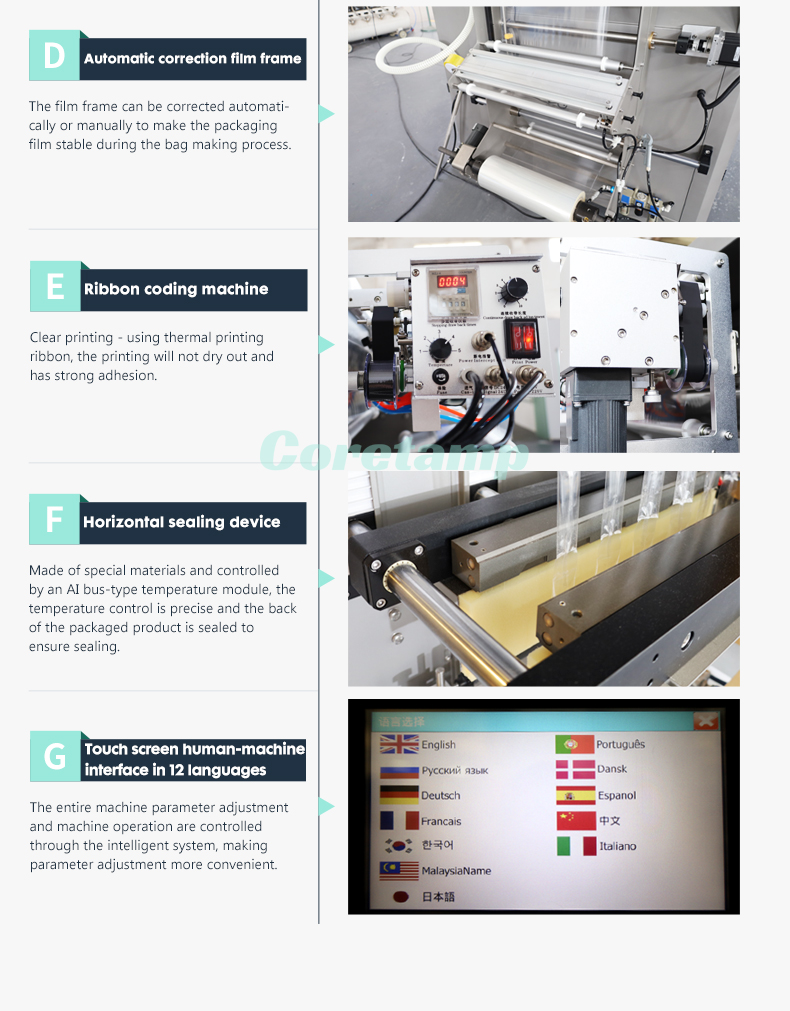

4. There are 12 commonly used operating languages, which are simple to operate and have device fault prompts and self diagnostic functions

5. Electrical control adopts bus type PLC+bus type AC servo. Compared with other similar products, the pulse control method has a faster response and more precise control. The sealing response speed and accuracy are both within milliseconds, and the multi axis control has good synchronization, thereby improving the packaging speed

6. The entire bar packaging machine complies with EU CE safety standards, the wires have EU CE safety certification, and the main electrical components have North American CUL safety certification

7. Standard configuration of small bag packaging machine

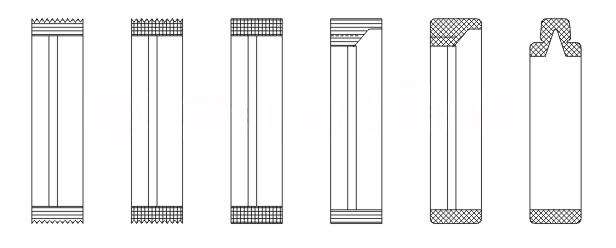

Bag Type:

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum granule packing solution to you for reference. Thank you.

1. Bag size

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Specification:

| Model | LC-500B-04P | LC-500B-06P | LC-500B-08P | LC-500B-10P | LC-500B-12P |

| Lane Number | 4 lanes | 6 lanes | 8 lanes | 10 lanes | 12 lanes |

| Bag Width | 16-50mm | 16-50mm | 16-50mm | 16-50mm | 16-50mm |

| Bag Length | 40-170mm | ||||

| Packing Speed | 30-80 Bags/Min/Lane | ||||

| Control System | Bus type PLC+Bus type AC servo | ||||

| Cutting Type | 1.Flat Cutting, 2.Zigzag Cutting, 3.Continuous Cutting, 4.Customized Special Shap Cutting | ||||

| Optional device | Date Coder, Air-filling Device, Tear Notch Device | ||||

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

6 Lanes Multi-Line Granule Stick Sachet Packaging Machine

Copyright © CoreTamp All Rights Reserved | Sitemap | Powered by