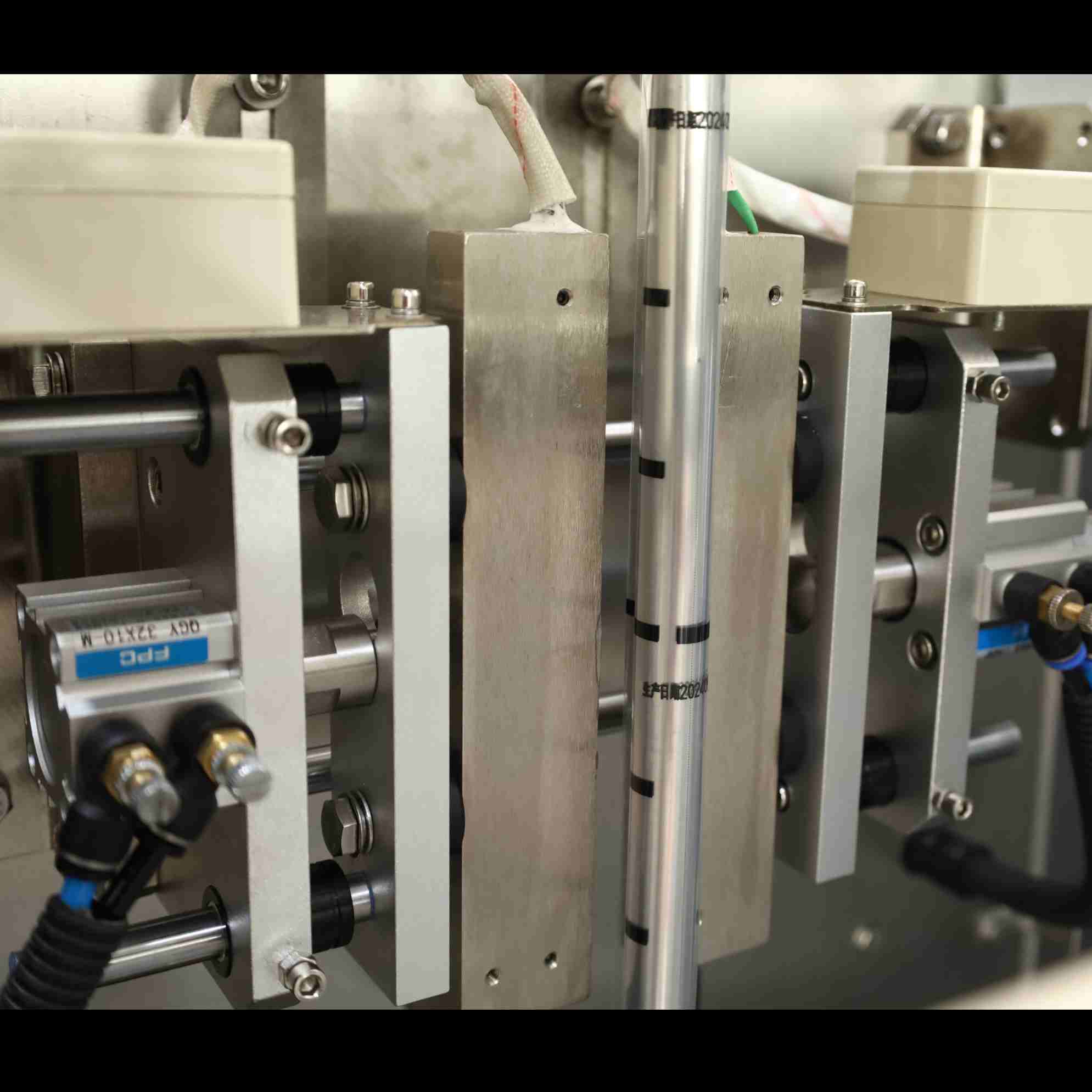

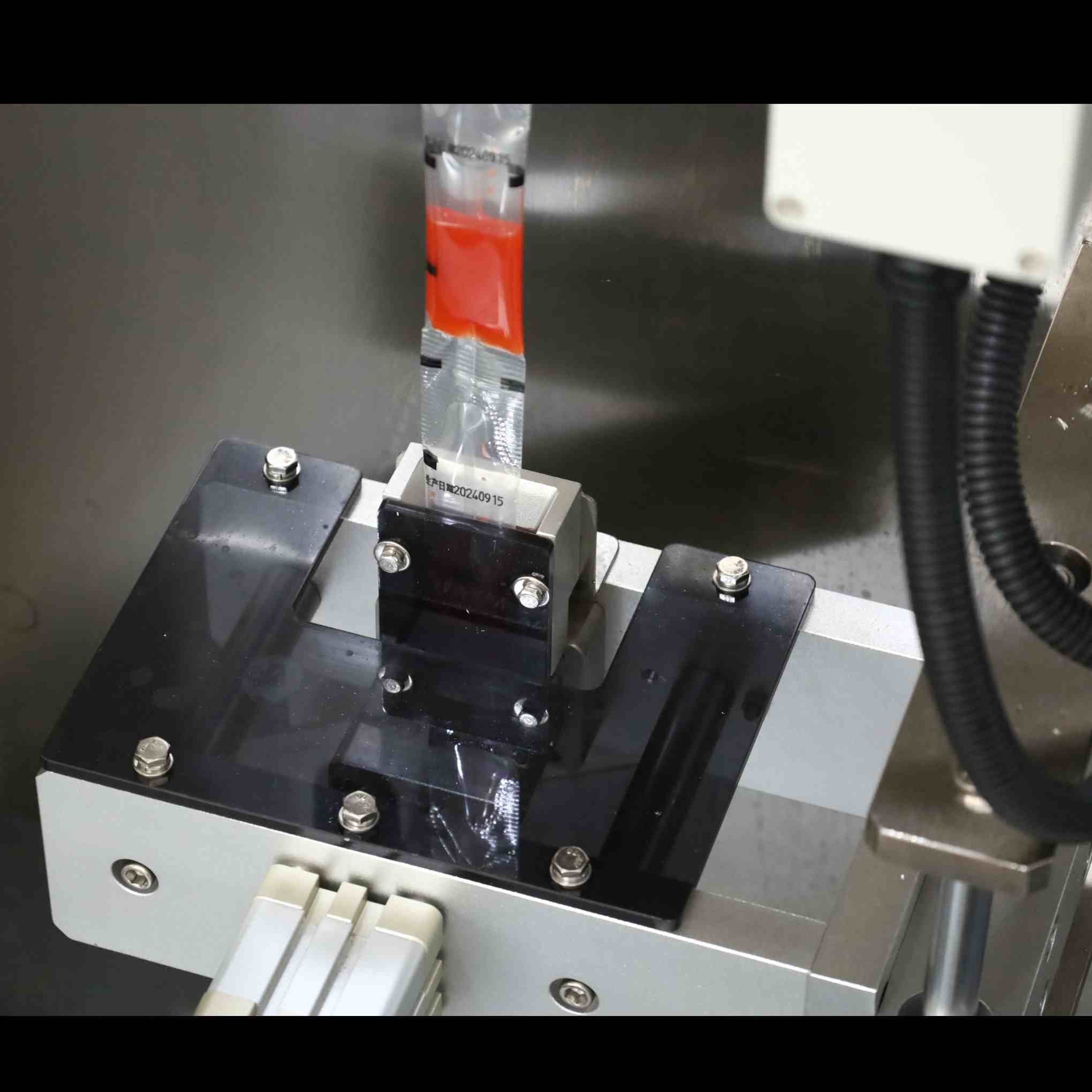

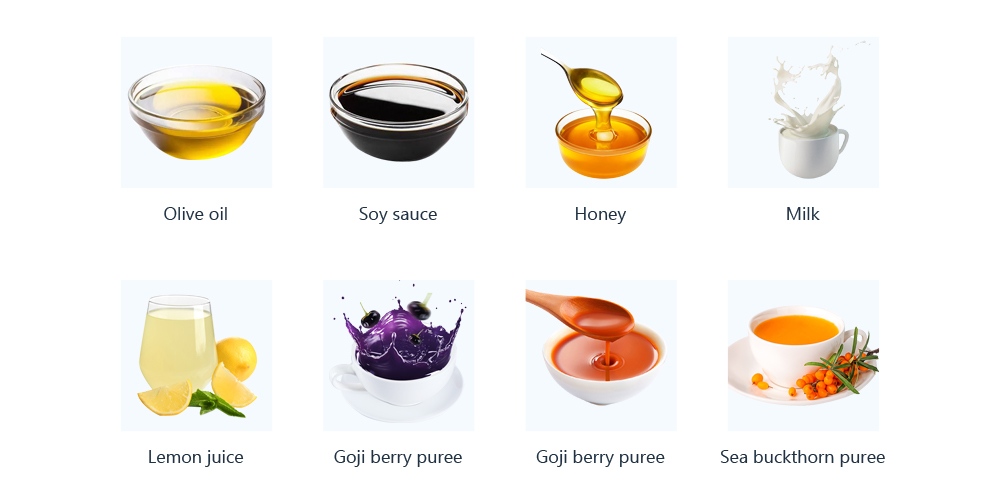

The liquid (paste) filling system is a high-precision gear pump quantitative filling device refined by CNC SUS316L stainless steel material, which has high precision, strong versatility, and is suitable for high-viscosity (pet food) materials.It is equipped with a general cleaning device as standard, but it can also be combined with a CIP cleaning system.

Easier maintenance

All parts in contact with the packaged material can be quickly disassembled and installed.

1.Efficient anti-fingerprint: the device is easy to clean.

2.System configuration: programmable bus system + bus servo, fast response and more accurate.

3.Color mark control: The color sensor is used to grab the color punctuation points of the packaging film to ensure the integrity of the pattern.

4.Applicable to digital factory: In response to the requirements of Industry 4.0 trend, it can be connected to SCADA and MES systems.

5.12 commonly used operation languages: simple operation, with equipment fault prompt, self-diagnosis function.

6.Safety & Certification: Comply with GMP production standards, the whole machine is CE certified, and the electrical configuration is CUL certified.

7.Food-grade stainless steel: The whole machine is made of SUS304 stainless steel, and the part in contact with the material is made of SUS316.

8.Temperature control mode: Bus type temperature module and independent temperature control, temperature accuracy control within ±0.1 degrees,Temperature display and setting are operated on the touch screen.

9.Automatic identification system for film breakage and film shortage: automatic alarm shutdown, film roll correction and docking device.

| Model | LC200B+9832G-06N | LC200BS+9832G-06N | LC200F+9832G-06N |

| Metering system | Piston Pump | ||

| Bags/Minute | 20-40 cuts/min | ||

| Film roll width | Max.170mm | Max.160mm | Max.160mm |

| Film roll inner diameter | 75mm | ||

| Film roll outer diameter | Max.300mm | ||

| Bag width | 16-80mm | 16-80mm | 30-80mm |

| Bag length | 50-160mm | ||

| Sealed type | Back sealing | Three sided sealing | Four sided sealing |

| Cut type | 1. Round corner cutting; 2. Flat incision; 3. Sawtooth cutting | ||

| Power | 220V 1P 50 Or 60HZ/5KW | ||

| Air consumption | Air pressure/consumption:17-25L/min(0.6-0.8MPa) | ||

| Machine weight | 300KG | ||

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Liquid Sachet Packing Machine

Copyright © CoreTamp All Rights Reserved | Sitemap | Powered by